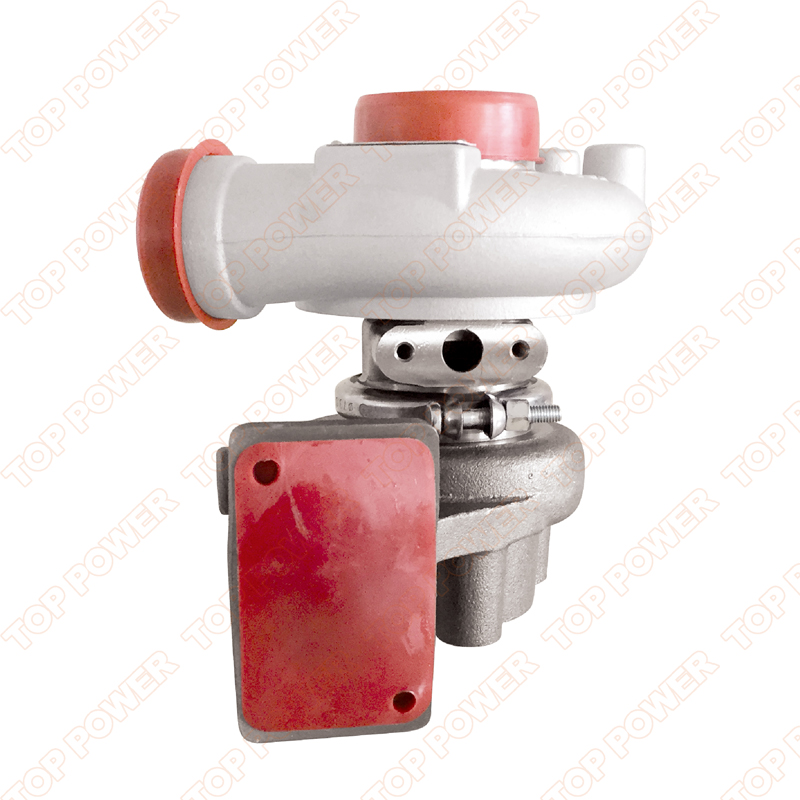

New Precision CNC Line Boosts Production Quality at Top Power Facility

Top Power is pleased to announce the addition of a high-precision Tsugami CNC machining cell to its production floor — a move that strengthens the company’s commitment to delivering consistent, high-quality turbocharger components to global customers. The new installation, pictured above, is already having an immediate impact on throughput, repeatability, and quality control.

The Tsugami unit, equipped with an advanced control panel and enclosed machining bay, is dedicated to producing critical small components that demand exacting tolerances. In the foreground of the photo, freshly machined valve stems and related parts rest upright in a protective foam tray, ready for inspection. This visual captures the careful handoff between automated machining and manual quality checks — a process Top Power has refined to ensure every part meets specification before shipment.

Why this investment matters

Turbocharger components operate under extreme temperatures and rotational speeds, so dimensional accuracy and surface finish are non-negotiable. The Tsugami cell delivers micron-level repeatability and a superior surface finish, reducing downstream assembly issues and improving the longevity of final turbocharger assemblies. By tightening tolerances at the machining stage, Top Power can reduce rework and scrap rates, lower lead times, and offer more reliable delivery schedules to partners.

Integrated quality and efficiency

The new cell is not just about metal removal; it’s part of a broader workflow that connects CNC machining, visual inspection, and packing. The machine’s enclosed environment helps control chips and coolant, while the ergonomic layout seen in the image supports safe, efficient operator interaction. Parts are staged immediately after machining for prompt dimensional and surface inspections, ensuring only parts that pass stringent checks proceed to finishing and assembly.

A step forward for customers

For distributors and OEMs, the tangible benefits are clear: tighter tolerances, better surface integrity, and more consistent delivery. Top Power’s investment in modern machining capability reinforces the company’s promise to supply performance-oriented components that meet or exceed industry expectations.

Looking ahead

Top Power will continue to expand targeted automation and precision machining where it delivers the most value. This Tsugami cell is the latest example of how the company blends technology and craftsmanship to serve customers who demand durability and performance.

For inquiries about our components or to arrange a factory tour, contact Top Power’s sales team.