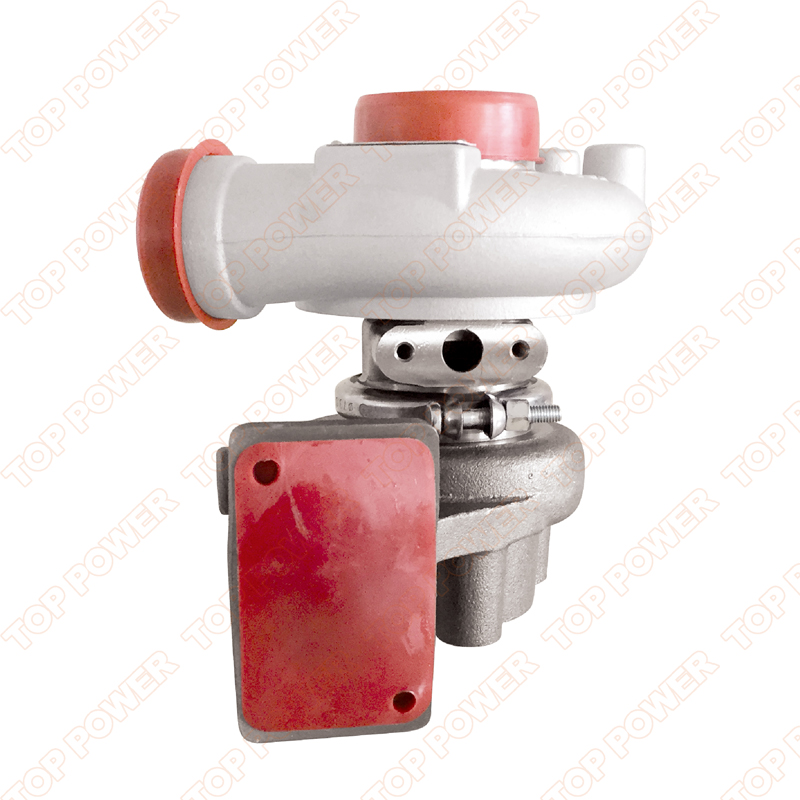

New Precision Honing Process — 100% Guaranteed Center-Bore Finish & Concentricity for CHRA Intermediates

Fengcheng Top Power Co., Ltd is proud to announce the launch of a dedicated precision honing and inspection workflow specifically for center housings (CHRA intermediates). This new process was developed to 100% ensure the center-bore surface finish and concentricity of every intermediate we produce — a critical factor that directly affects bearing life, rotor balance, and overall turbocharger reliability.

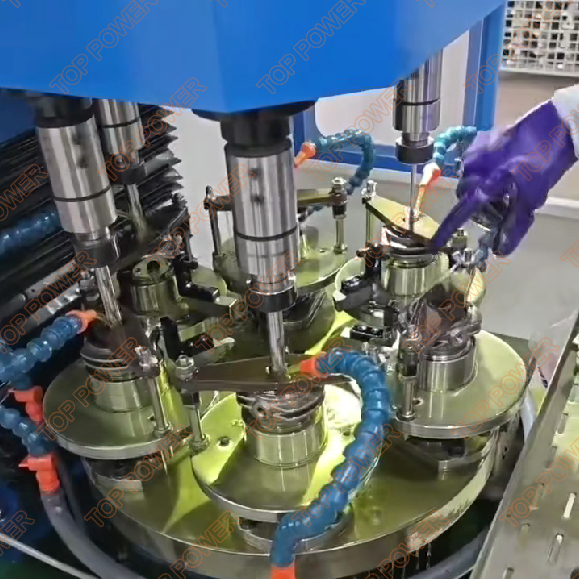

We combine purpose-built honing fixtures with controlled-stroke CNC hone heads and in-line referencing to remove machining marks, correct micro-geometry, and deliver a consistent, high-quality surface finish. Immediately after honing, every part is measured using in-process gauges and final verification equipment (roundness/centering gauges and profilometers). Any deviation outside our strict tolerances triggers a hold-and-review step so only parts that pass full inspection move forward to assembly.

Key process highlights

CNC-controlled honing for repeatable material removal and bore geometry refinement.

Fixture-based referencing that aligns the intermediate to datum points used throughout machining and assembly.

100% in-line inspection — roundness, runout, and surface-roughness checks performed on every single part.

Traceable records — each part’s measurement data is saved with batch and serial identifiers for auditability.

Corrective loop — out-of-spec parts are quarantined and reworked or analyzed to prevent recurrence.

Customer benefits

Lower vibration and improved rotor balance because the bearing bore is concentric to rotation axes.

Extended bearing and seal life thanks to a smoother, more uniform bore surface.

Fewer field returns and improved uptime for end-users.

Faster approvals — we can provide per-batch inspection reports and raw measurement files to support your validation.

“Center-bore quality is one of those behind-the-scenes details that makes a big difference in turbocharger longevity,” said our Quality Manager. “By investing in a full honing-and-inspection loop and making 100% verification standard practice, we remove guesswork and give our customers confidence in every intermediate that leaves our floor.”

If you’d like technical specifications for our honing tolerances, sample inspection reports, or to arrange parts for evaluation, please contact our export team. We welcome technical queries and can provide on-request CMM reports and balancing data to support your approval process.