🏭 TOPPOWER Showcases Precision Mastery: Five-Axis CNC Machining Center Sculpts an Eagle, Demonstrating World-Class Turbocharger Manufacturing Expertise

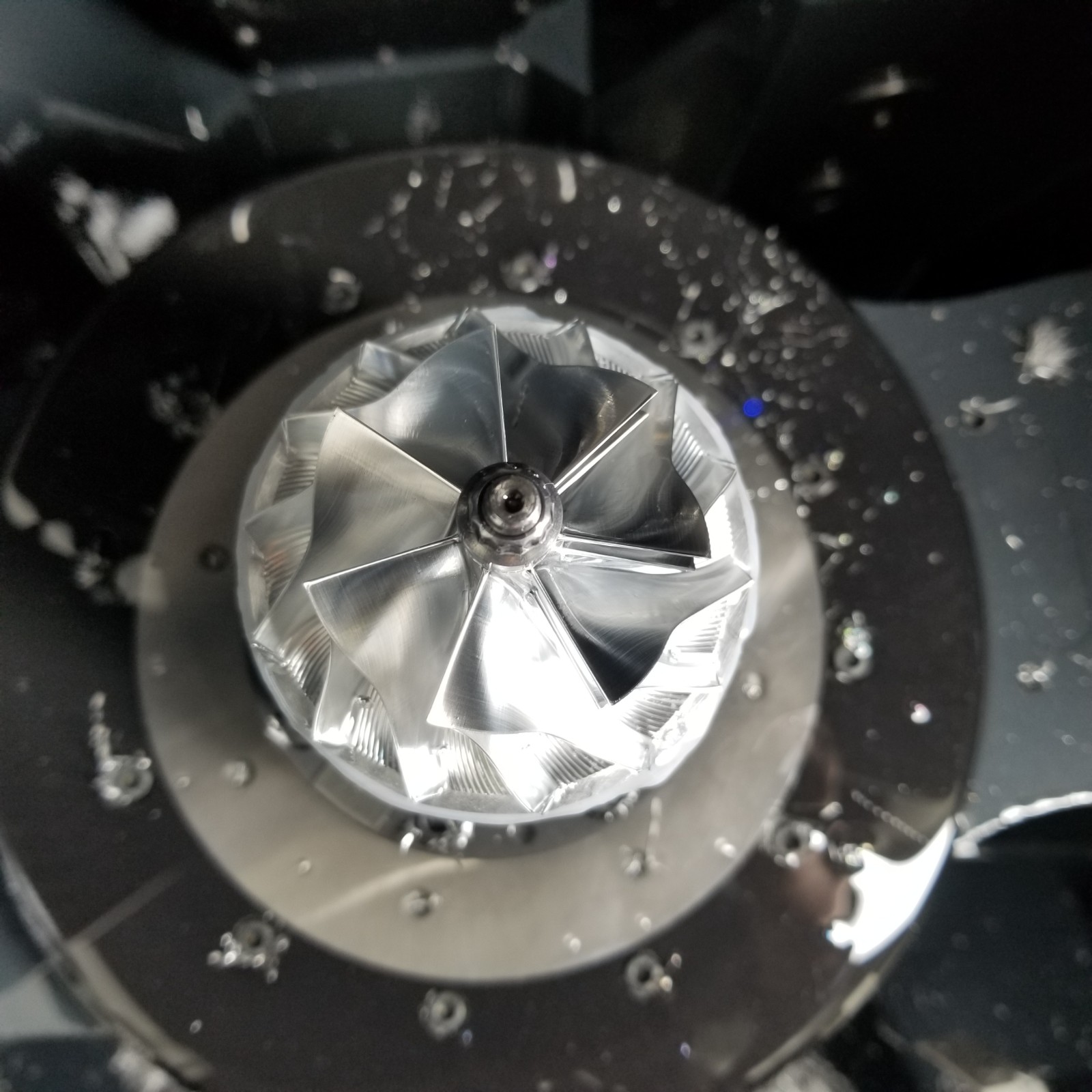

In an extraordinary fusion of engineering and artistry, TOPPOWER has unveiled a captivating demonstration that bridges the worlds of high-tech manufacturing and aesthetic perfection. Using our advanced five-axis CNC machining center, our skilled technicians have crafted a stunningly detailed eagle sculpture, where each feather and curve embodies the precision, sophistication, and reliability that define our turbocharger manufacturing process.

Engineering Meets Art – The Eagle Project

At first glance, the eagle might seem like an unconventional subject for an industrial manufacturing demonstration. Yet, it is precisely this choice that makes the project remarkable. The eagle — a symbol of vision, power, and precision — mirrors the qualities that TOPPOWER upholds in every product we manufacture.

Under the steady hum of the five-axis machining center, a solid block of aluminum was meticulously transformed into an intricately detailed eagle. Every delicate curve of the beak, every fine contour of the wings, and every overlapping layer of feathers was carved with micrometer-level accuracy.

This demonstration was not merely an artistic pursuit — it was a powerful statement of our engineering capabilities. In turbocharger manufacturing, such precision is not optional; it is essential.

Why Five-Axis CNC Technology Matters

While traditional three-axis machining operates on X, Y, and Z planes, a five-axis CNC machining center adds two additional rotational axes. This allows for unparalleled flexibility, enabling complex geometries to be machined in a single setup.

Key Advantages in Turbocharger Manufacturing:

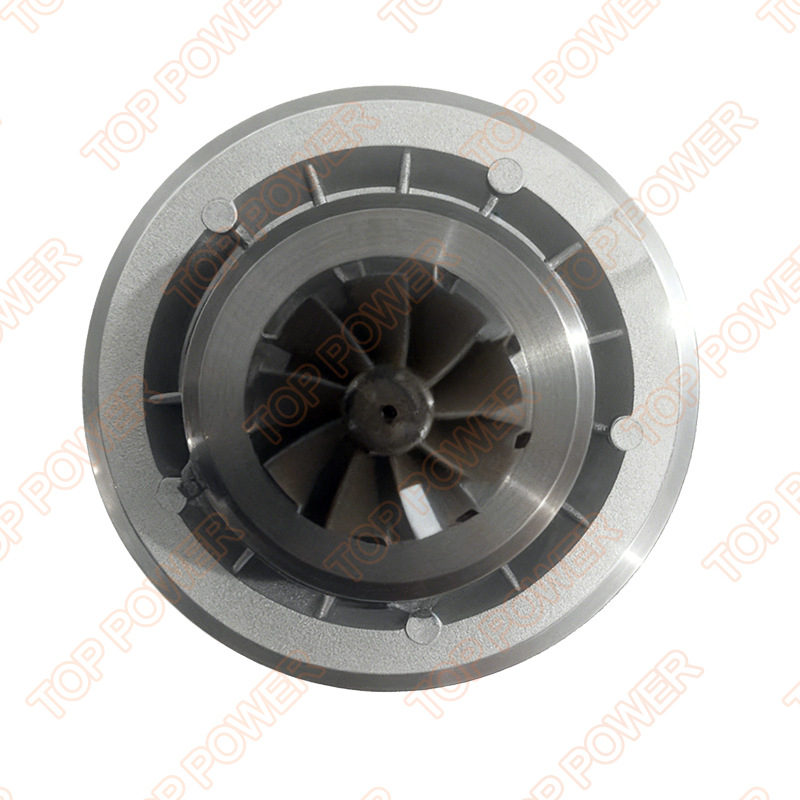

Complex Contour Machining – Ideal for components like turbine and compressor housings, which feature intricate curves and varying thicknesses.

Fewer Setups, Greater Accuracy – By machining from multiple angles without repositioning, we reduce cumulative errors, ensuring ultra-precise parts.

Higher Surface Quality – Smoother finishes lead to improved airflow efficiency, directly impacting turbocharger performance.

Increased Efficiency – Shorter production times without compromising accuracy mean faster delivery for our customers.

Design Freedom – Capability to manufacture prototypes and custom designs quickly, enabling rapid product development.

The eagle sculpture is a tangible example of how five-axis machining handles intricate details. In turbochargers, these details translate to precisely balanced rotors, optimally shaped blades, and perfectly aligned housings — all critical for efficiency and durability.

About TOPPOWER

TOPPOWER specializes in the development, manufacturing, and export of turbochargers for passenger cars, commercial vehicles, and performance applications. With cutting-edge facilities, advanced testing equipment, and a dedicated engineering team, we deliver products that meet or exceed global standards.

Contact:

Fengcheng Top Power Co., Ltd.

No. 4, 3rd Road, Zone B, Erlong Industrial Park

Fengcheng City, China

📧 Contact: tiana@toppower818.com

🌍 Website: www.toppower818.cn

📱 WhatsApp: +86 18840577547

From the delicate feathers of an eagle to the powerful fins of a turbocharger — precision is our passion.