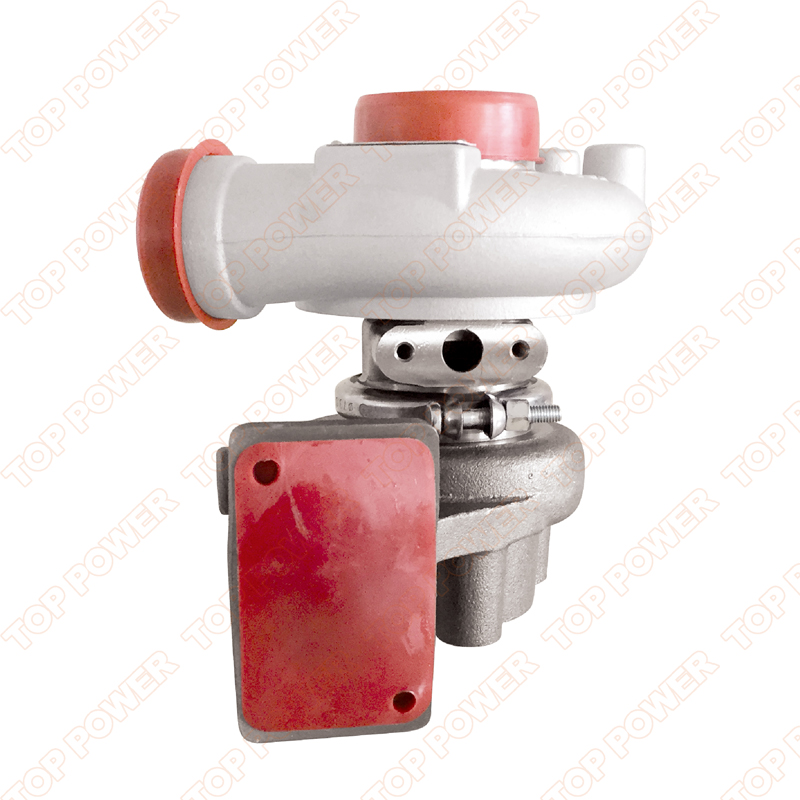

🏭 TOPPOWER Upgrades Factory Equipment to Deliver More Efficient, Precise, and Reliable Turbochargers

As the global demand for high-quality turbochargers continues to rise, TOPPOWER has taken a major step forward by investing in a full-scale upgrade of our production equipment. This strategic move reinforces our commitment to manufacturing excellence, ensuring that every turbocharger we deliver meets the highest standards of performance, precision, and durability.

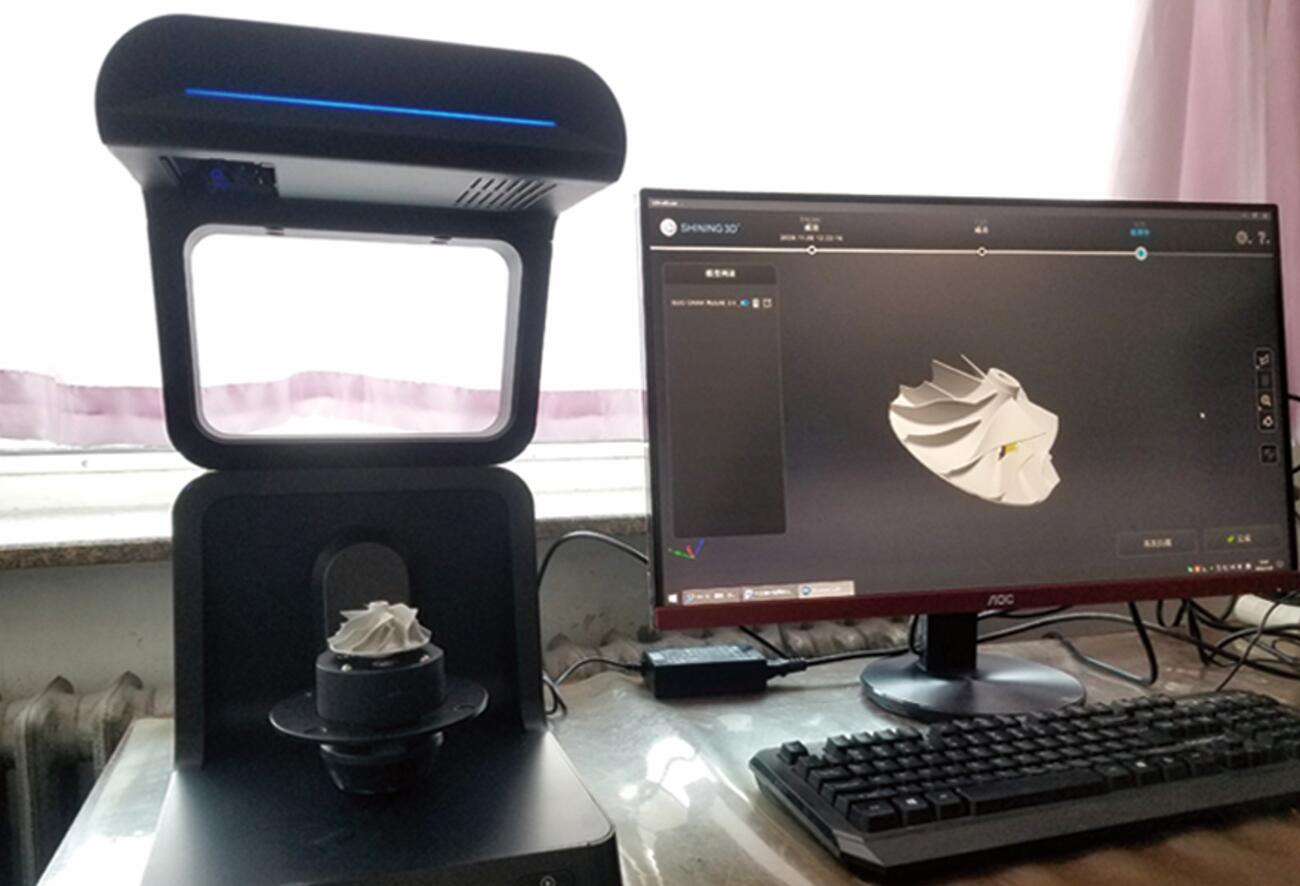

Over the past few months, TOPPOWER’s factory has introduced a wide range of advanced production equipment, including:

CNC Machining Centers

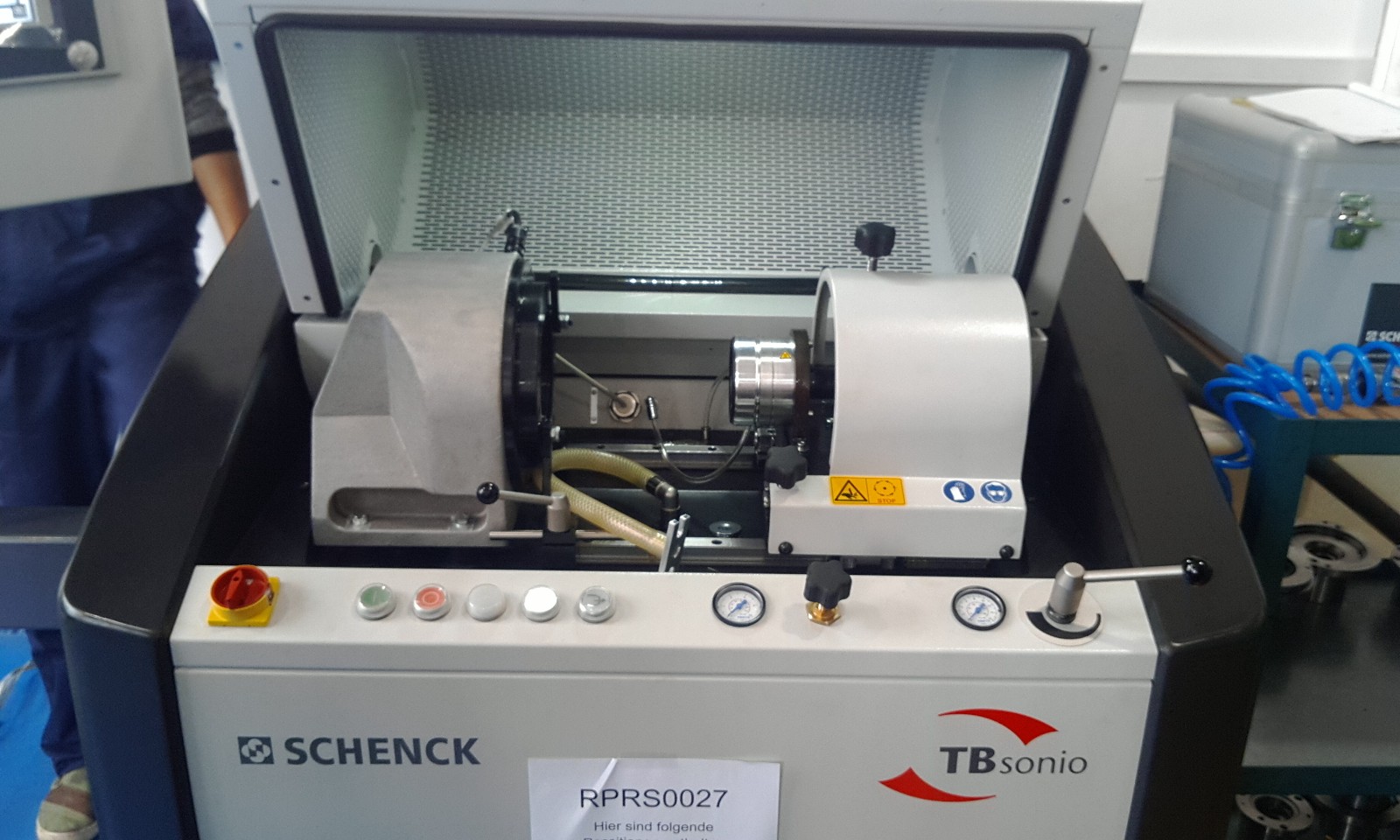

Dynamic Balancing Machines

High-Speed Core Assembly Testing Machines

Leak Testing Equipment

Automatic Shaft Balancing Systems

Torque-Controlled Assembly Stations

These upgrades have significantly improved our manufacturing capabilities across all stages of turbocharger production. Our CNC machining centers ensure micron-level precision for turbine and compressor housings, reducing error rates and enhancing the overall product lifespan. The dynamic balancing machines and high-speed rotor testers are critical in ensuring vibration-free, high-speed performance — a must for modern turbochargers operating at 100,000+ RPM.

At TOPPOWER, we understand that quality doesn’t happen by accident — it is the result of rigorous engineering, advanced machinery, and strict process control. From raw material selection and housing casting to final assembly and quality inspection, every process is monitored under a tightly controlled quality management system. Each turbocharger undergoes:

Shaft balancing (low-speed and high-speed)

Seal and pressure testing

Rotor speed and vibration tests

Air leakage and oil leakage simulation

These checks ensure our products maintain optimal performance under real-world operating conditions, whether installed in daily-use passenger vehicles, commercial fleets, or performance-modified cars.

With the newly upgraded facility, TOPPOWER’s annual production capacity now exceeds 100,000 units, making us well-equipped to handle both small-batch custom orders and high-volume OEM/aftermarket demands. Whether your business operates in the Middle East, Africa, Latin America, or Southeast Asia, we are fully prepared to support your turbocharger sourcing needs with short lead times, stable quality, and competitive pricing.

What also sets TOPPOWER apart is our in-house R&D and engineering support. We are capable of developing new turbo models based on samples, drawings, or OE specifications provided by customers. Our team of experienced engineers works closely with clients to optimize product performance and compatibility across a wide range of engine platforms — including Garrett, BorgWarner, IHI, Mitsubishi, Toyota, and other popular brands.

In today’s competitive automotive aftermarket, having a reliable supplier is more important than ever. That’s why we also offer the option of remote video factory inspections, live virtual meetings, and real-time production updates — giving you complete transparency and confidence when working with us.

At TOPPOWER, our goal is simple:

To be your trusted turbocharger manufacturing partner, delivering consistent quality and long-term value.

We warmly welcome global customers, distributors, and sourcing agents to get in touch with us for factory tours, product catalogs, and cooperation opportunities. Let us grow together in the exciting and fast-moving turbocharger market.

📧 Contact: tiana@toppower818.com

🌍 Website: www.toppower818.cn

📱 WhatsApp: +86 18840577547